KWP

Overview

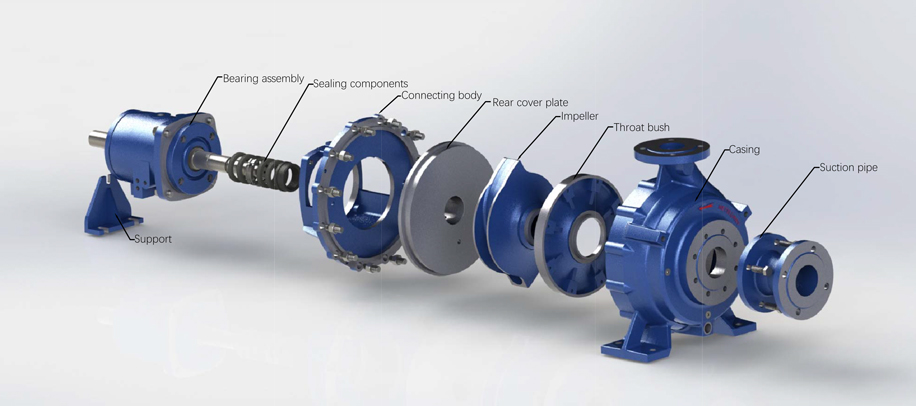

The KWP type non clogging centrifugal pump is a horizontal, single-stage, axial suction centrifugal pump. It can be used in urban water supply, sewage treatment engineering, chemical processes, steel and papermaking, sugar making, and canned food industries. The main characteristics are high efficiency and no blockage. Adopting a rear dismantling structure, the rotor components can be disassembled without dismantling the inlet and outlet pipelines and pump body, simplifying maintenance. The impeller and Cover Plate Liner Insert can be quickly replaced to enable the pump to quickly adjust to different working conditions.

The KWP pump can transport clean water, various types of sewage, seawater, brine, wastewater, and sewage slurry. Therefore, it is suitable for flood control plants, sewage treatment plants, breweries, mines, as well as chemical and construction industries.

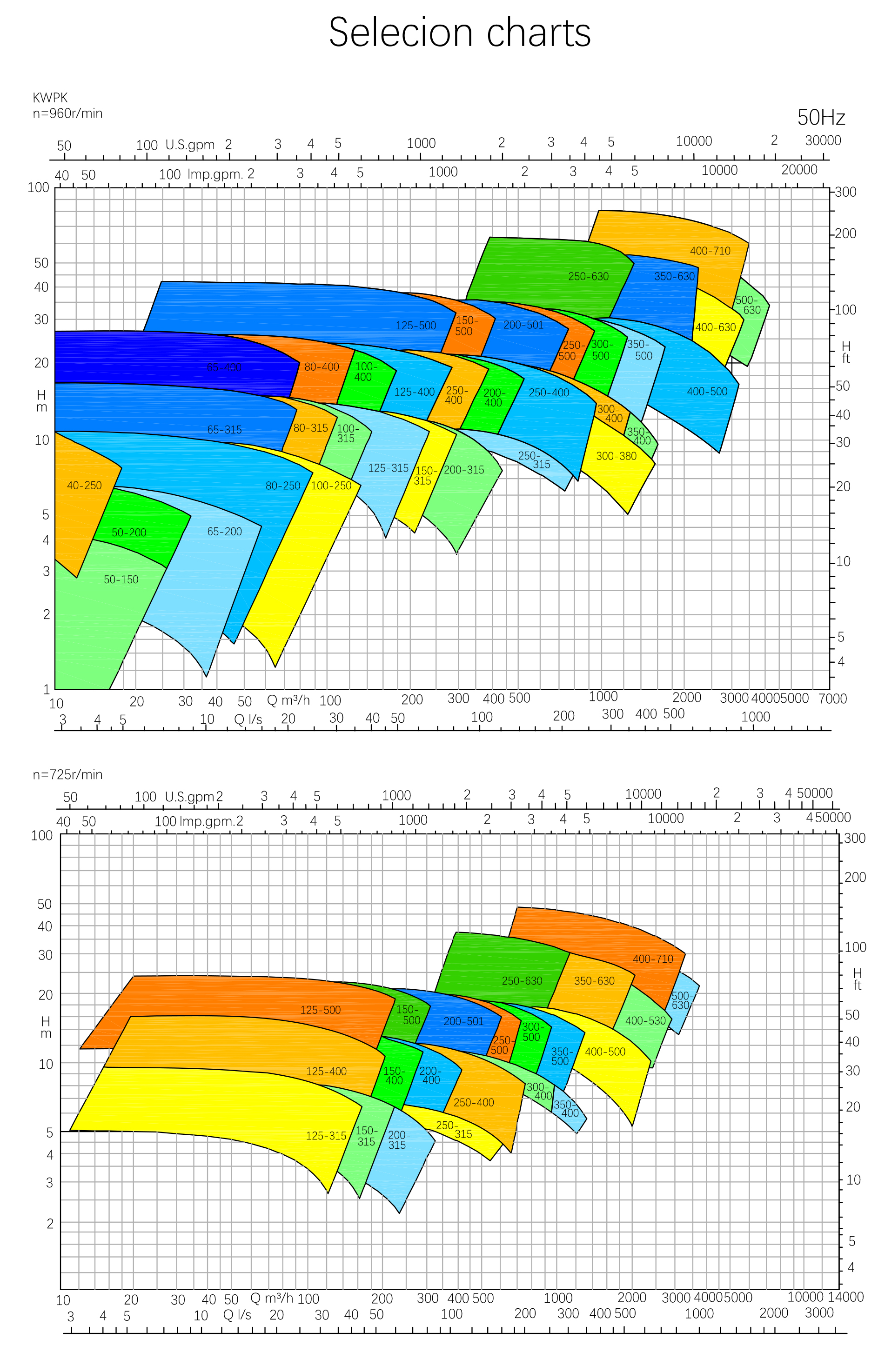

The specification range of KWP pumps based on outlet size is from 40mm to 500mm.

KWP pumps are generally suitable for conveying neutral media, with a pH value of around 6-8. For transporting corrosive media with special requirements, corrosion-resistant or wear-resistant materials can be selected.

Sealing form

Packing seal: There are two types of structures: standard and high-temperature. When the temperature of the conveying medium exceeds 90 ℃, a high-temperature type should be used. This type of packing box is equipped with a cooling box, which is filled with cooling water to facilitate high-temperature conveying conditions.

Mechanical seal: In situations where the conveying medium cannot leak, mechanical seal can also be used. Mechanical seals have single and double end faces, which can be selected according to different occasions.

Home > Product

Home > Product